This is a cross-post. The original is here.

Join the 2017 LeSS Conference in London to find more discussions

like this.

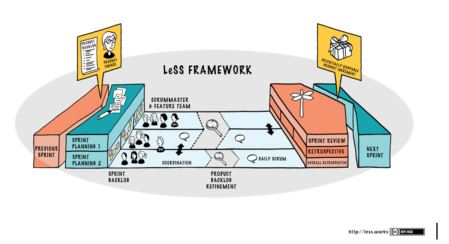

Large Scale Scrum (LeSS). It is the framework for scaling agile development, done by multiple teams, as they work on same product and work for a single Product Owner. In order to be effective, LeSS requires organizational descaling that means simplification/flattening of organizational design.

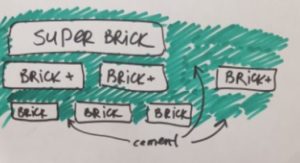

What is Organizational Design? To understand it better, let’s look for analogy in construction industry. What is required to erect a building? In our analogy, we shall stay simple: bricks (foundation block) and cement (connective material that holds bricks together).

Imagine two buildings: Building A and Building B.

Building A uses brick as its main foundation block. In fact, when looking at the building’s facade, the most prevalent object, caught by a naked eye, is a brick. Bricks are positioned next to one another, with just enough cement in-between to glue them strongly together. There is no excess of cement anywhere: the connection layer is very thin/lean.

Architectural design of building A is simple and flexible: the structure is flat (one-story high) and it sits on strong foundation, also made of brick. Because of its design, architectural adjustments are possible in various sections of the building, independently, with little additional labor. Due to such modular structure, the building can be expanded laterally, just by adding more bricks to the wall. Of course, due to its flat structure, the building is also very stable and can withstand a strong wind, flood or an earthquake: practically nothing can be shaken off or washed off the building.

When waste is produced inside the building, it becomes noticeable immediately. Waste disposal is also very simple: it does not require complex chutes or automated waste ‘packaging’ systems. Waste removal can be mostly done manually, by building residents. Any necessary supplies (e.g. food, water, furniture, other materials) can be easily delivered to any building area, without the need of advanced technology or mechanics.

Finally, building inspection and maintenance is a very easy process, because of flat structural design: foundation, walls and floor assessment – all can be performed with a naked eye; corrections can be done timely and efficiently.

This is what building A looks like:

Building B is made of a very few bricks and a lot of cement in-between that holds bricks together. In fact, the ratio (by weight) of bricks-to-cement is very low.

Architectural design of building B is rigid. It has many floors, with top floors made primarily of cement. The building represents a heavy and monolithic structure, and although it also sits on brick foundation, as building A, the bricks are widely spaced with lots of cement in-between. This means that the overall weight of building B is dangerously high (foundation can crack). The building’s expansion limit, to accommodate growing occupancy demands, is low: it cannot be easily extended (scaled) horizontally with a couple of extra bricks added to the side, because the bottom brick layer would require multiple horizontal cement layers added on top – to follow the originally intended building design. If additional cement layers are added on the top of foundational brick layer this will further increase risks of foundation cracking.

Waste disposal is a serious issue for Building B. While waste can be relatively easy removed from the bottom floor (it is also not in abundance there) and, to some extent, from top floors (by taking it to the roof and using a waste removal chopper !:-) ), there is a huge amount of waste that gets accumulated at middle floors – and it sits there. It is extremely challenging to remove this mid-section waste and what building management does from time to time, is ordering for this waste to be moved from one floor area to another (the building is very compartmentalized). Sometimes, waste gets moved to floors above; sometimes – below. This creates an illusion of waste removal. But waste remains.

Delivery of supplies and food to Building B occupants is a real challenge, especially if elevators are out of order. This makes occupants angry and frustrated and sometimes they turn onto each other; become competitors and rivals.

Finally, building inspection and maintenance is a nightmare for Building B. Many living units are out of compliance with building codes, but violations (and violators) are hard to identify and remove because true facts are well concealed and numbers are gamed by building occupants.

This is what building B looks like:

Large Scale Scrum requires organizational design that is analogous to the construction represented by Building A.

In LeSS:

Team represents the main building block (a brick). Selected team representatives (developers) and mentors-travelers–ensure effective coordination/connection between teams. There are no additional roles required for coordination. Cross-team events are minimal (Overall Product Backlog Refinement, Sprint Review, Overall Retrospective).

If product definition widens and more developers are included, another team can be formed and positioned laterally to existing teams – just like a brick. Should product definition become too wide and the number of required developers exceeds 50-60 people (8 teams), another product area can be identified (new independent module, made of bricks). Now, LeSS becomes LeSS Huge. The only additional coordination that would be required in LeSS Huge is between Area Product owners and Overall Product owner – for strategic planning of Potentially Shippable Product Increment (PSPI) at the end of every sprint. In both, LeSS expansion from 2 to 8 teams, and LeSS Huge expansion beyond 8 teams, there is no need for additional coordination that is different from what is described above (no extra cement needed to keep bricks together). Also, in LeSS Huge, when one Product Area expands and another one shrinks, moving the whole team from one area to another, does not require expansion or shrinkage of any additional “supportive” organizational layers.

By design, LeSS foundational structure is very lean: flat, fungible and cross-functional. There is no waste or overhead with roles, responsibilities, events or artifacts. Everything is very minimalistic. If any waste is generated in LeSS, it has practically nowhere to hide.

Because there is so much transparency in LeSS, waste is seen immediately. Any findings of waste or any other required improvements to individual teams or LeSS framework, can be effectively done in Team Retrospective or Overall Retrospective, respectively. Thanks to its flat organizational structure, LeSS (and LeSS Huge) don’t have to worry about waste removal from additional organizational layers – they [layers] just don’t exist. There are fewer layers that sit between LeSS teams and LeSS Product Owners and these layers are much thinner.

What happens with LeSS organizational structure during rough times: slow down in business, increased market competition? Arguably, because LeSS is so lean and there is continuous learning, it is much less likely that LeSS people will be displaced. LeSS is also more likely to withstand other types of reorgs and shake-ups because LeSS has very few moving parts, loose pieces or weak links.

Organizational designers that support LeSS think like building architects that want to build strong, reliable, easily-maintainable, low-waste, cost-effective and long-lasting structures!!!

Many thanks to all LeSS Trainers, Coaches and Practitioners building reliable structures ! ;-).

*Signed: ____The Organizational Building Management ! :-) ***